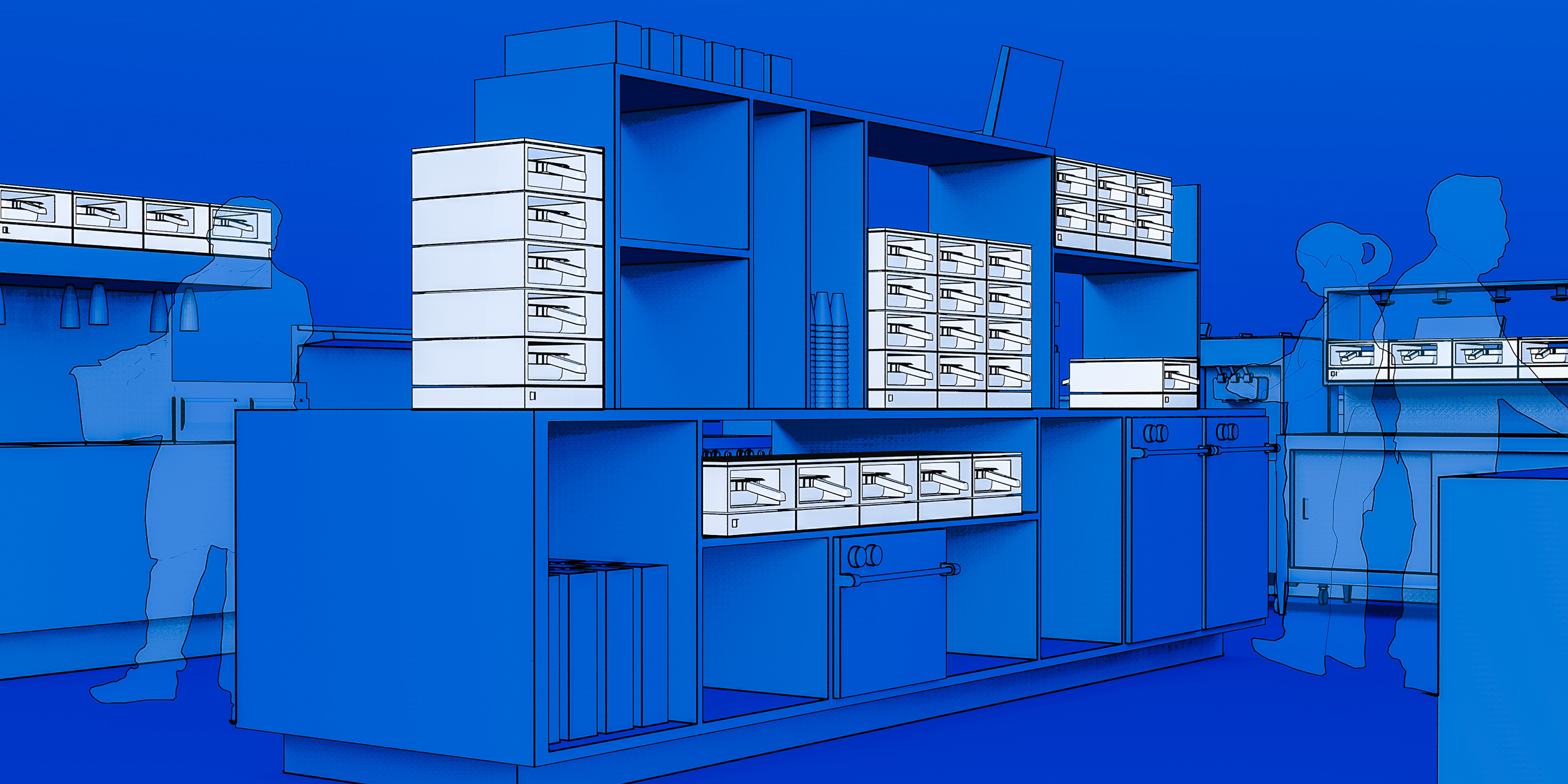

Holding bin sizes limit a restaurant’s ability to customize the system to fit their space. Users view and control each bin’s holding functions using additional interface equipment, like button panels and screens. As a result, these systems have a large, inflexible footprint, and user interfaces that can be confusing and text-heavy.

Prince Castle

Mechanical Design + UI/UX + Print Design

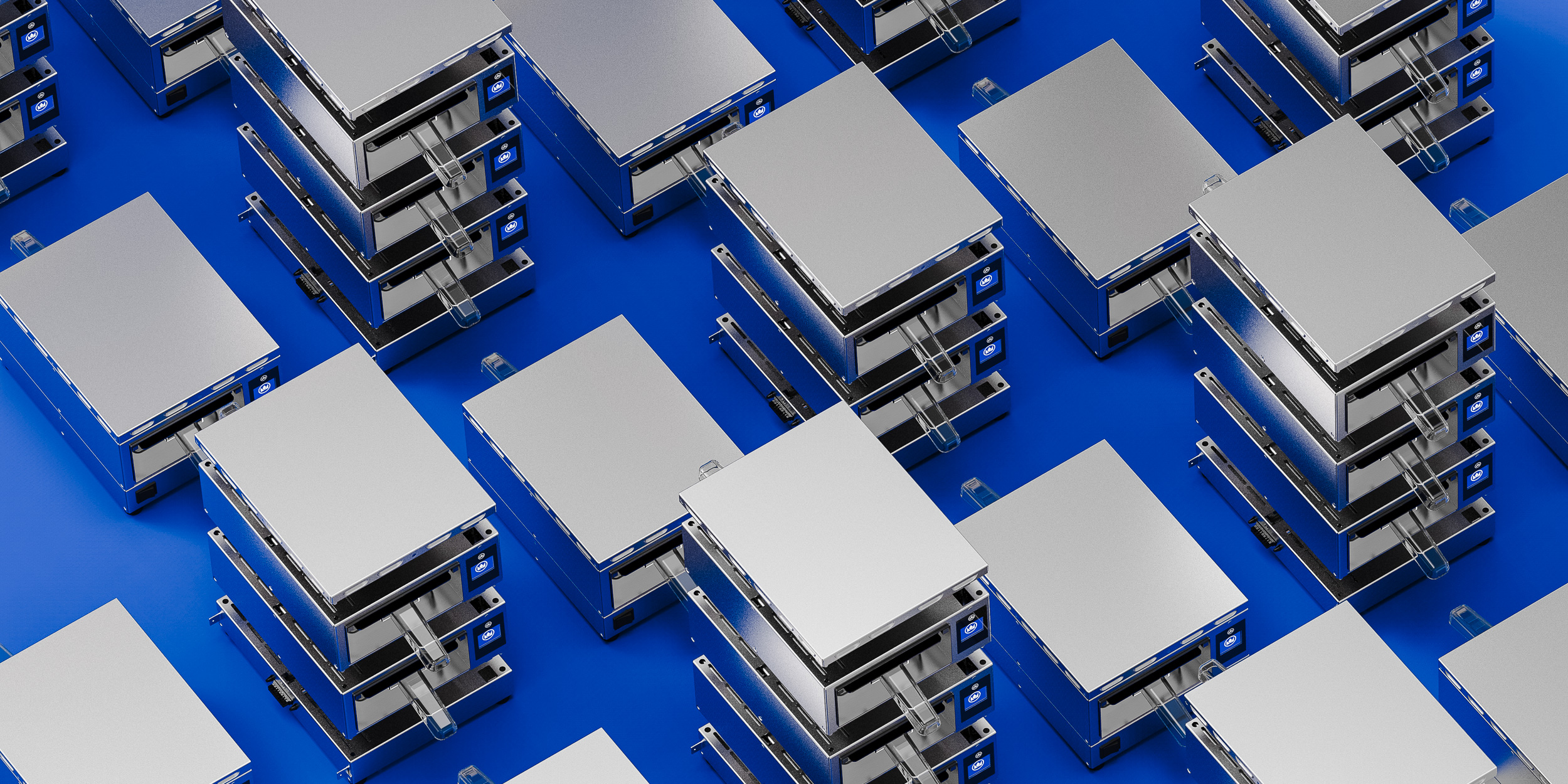

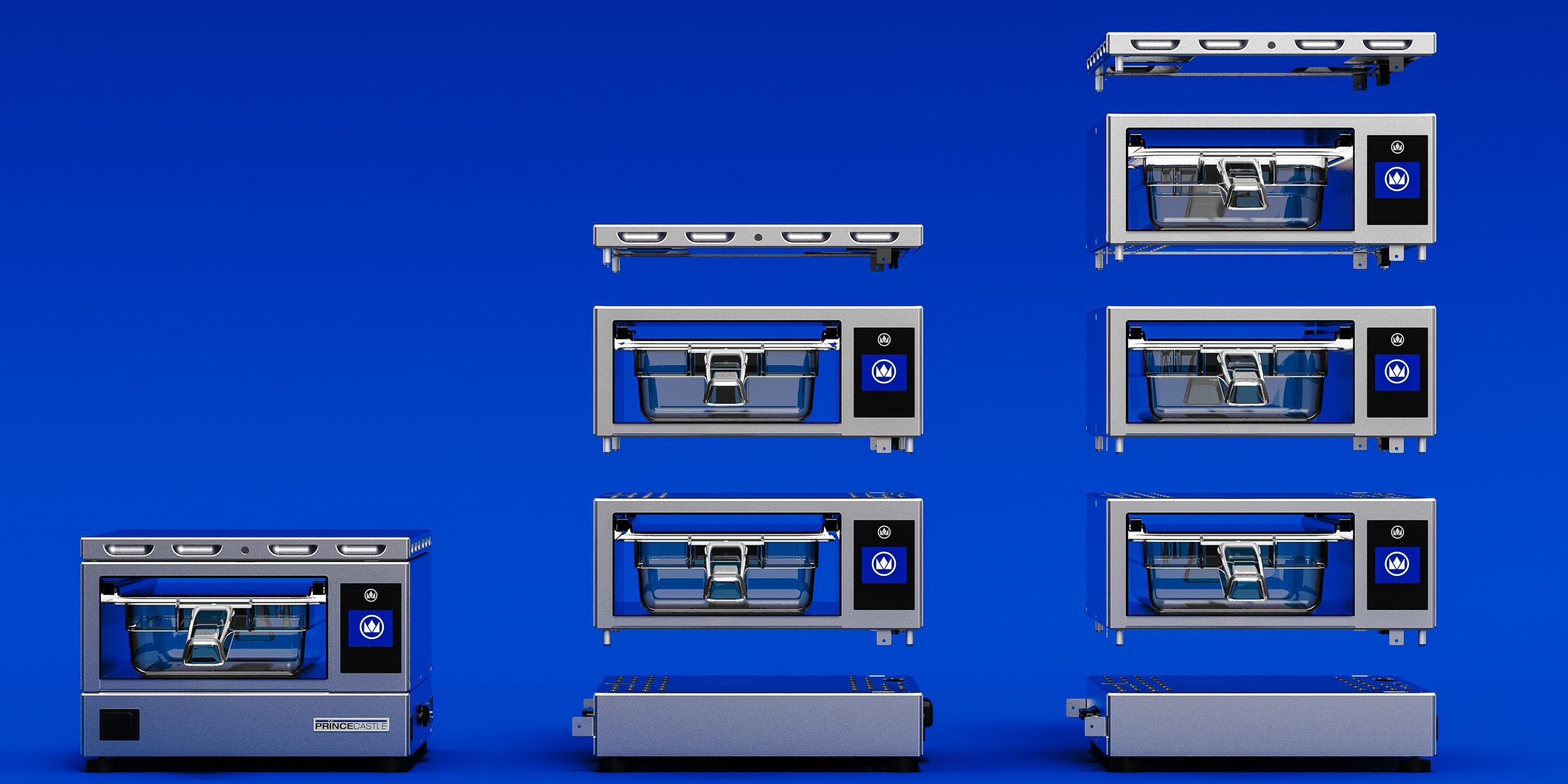

Holding systems are an essential component in foodservice environments, where prepared food items can be kept ready for serving in a system of individual heated shelves, or "bins". Prince Castle, a leading manufacturer of kitchen equipment, saw an opportunity to develop a modular holding bin system that would address the shortcomings of current bins and improve kitchen efficiency.

Industry // Commercial Kitchen Equipment

An industry first, the modular holding bin allows restaurants to configure their warming systems to meet their space and flow needs. Each bin is equipped with an LCD touch screen that provides direct control over bin functions, shelf temperature, and more intuitively monitor status on food freshness. The compact system can be configured to fit many footprints, and scales as needed depending on customer needs.

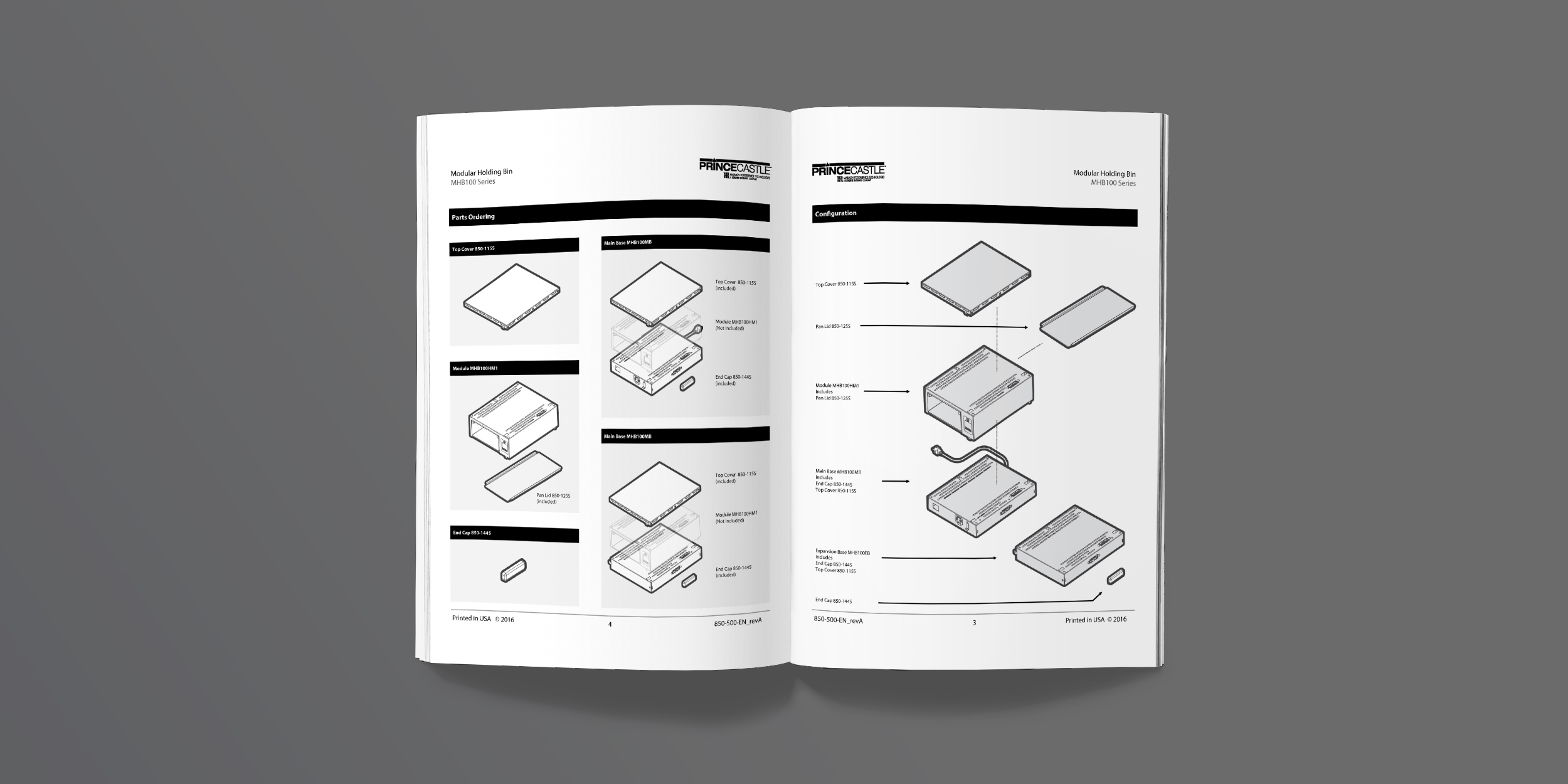

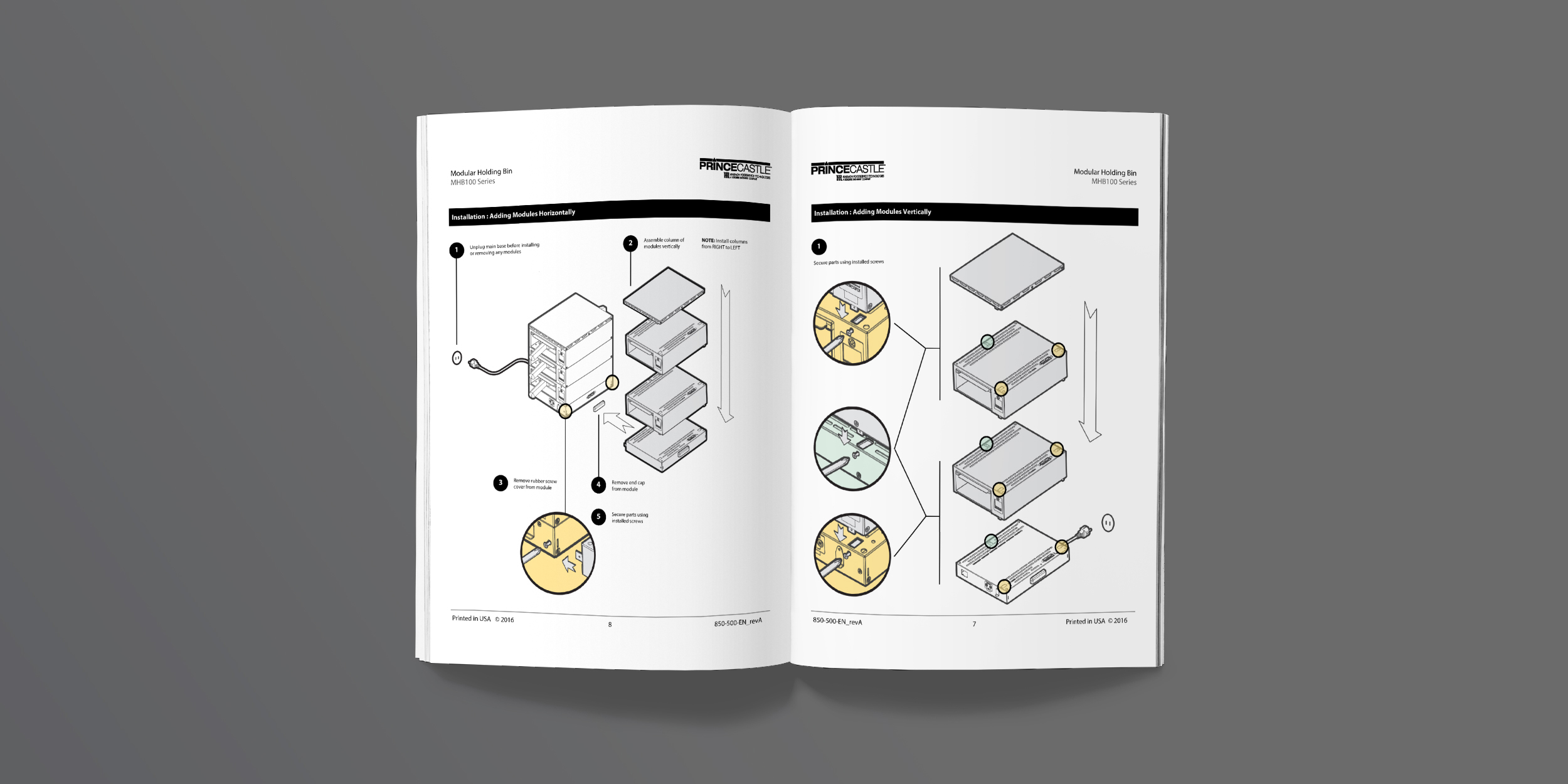

Ghost lab was involved with the development of the modular holding bin system from its inception. Our team collaborated on user research, creating initial concepts, rapid prototypes, and designing usage manuals.

Beyond industrial design and product layout concepts, Ghost lab also led the creation and design of the touchscreen user interface, and companion desktop control application. The pictorial-based design, also applied to the operational manuals, aims to eliminate the costly need for translation to other languages, and simplifies the crew training process. This graphical system has since become the basis for digital and printed user interface standards across all Prince Castle machines.